Introduction

Pumping stations are among the most energy-intensive elements in water infrastructure. According to industry data, energy costs related to pump operations represent up to 60-70% of the total operational costs of a typical water utility. In the face of rising energy prices and increasing pressure for sustainable development, optimizing energy consumption has become a priority for water infrastructure managers.

Analysis of the latest methods for optimizing deep well pump operations and reducing energy costs in medium and large water utilities shows that there is significant potential for savings. In this article, we present specific solutions that have been implemented in recent years in leading water treatment plants.

Experts estimate that a properly optimized system can deliver 20% to 35% energy savings, which translates into significant reductions in operational costs.

Key Optimization Areas

1. Implementation of Variable Frequency Drives (VFD)

One of the most effective ways to reduce energy consumption is the application of Variable Frequency Drives (VFD). These devices allow for precise adjustment of pump motor speed to current demand, eliminating the energy waste associated with running pumps at full speed when unnecessary.

In practice, the application of VFDs in water facilities brings immediate energy savings of 15-25%. Additionally, thanks to smoother pump startup and shutdown, mechanical wear of equipment is significantly reduced, which results in fewer failures and longer equipment lifespan.

2. Intelligent Control Algorithms

Next-generation SCADA systems, such as HydroNexis, utilize advanced control algorithms that analyze historical data, predict demand, and optimize pump operations in real-time. These systems are capable of:

- Predicting periods of peak water demand

- Automatically adjusting network pressure to current needs

- Selecting the optimal combination of operating pumps for a given flow

- Optimizing pump operation schedules considering energy tariffs

Implementation experiences show that the application of intelligent control algorithms alone can bring an additional 8-12% energy savings.

3. Monitoring and Data Analysis

The key to effective optimization is detailed monitoring and analysis of operational data. Modern SCADA systems provide:

- Continuous measurement of pump operating parameters (pressure, flow, power consumption)

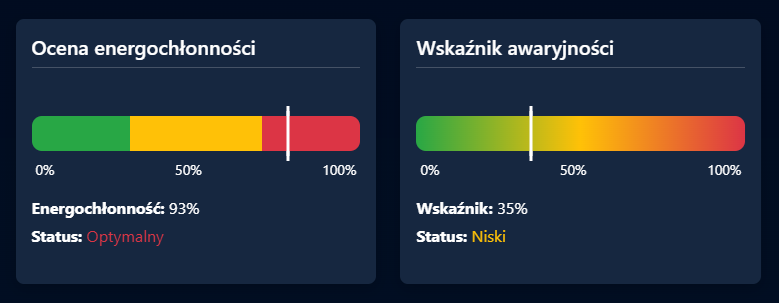

- Real-time calculation of energy efficiency indicators

- Detection of anomalies indicating potential problems

- Generation of reports and visualization of energy consumption trends

Chart: Typical energy consumption reduction after comprehensive optimization implementation in a pumping station

Case Study: Krakow Municipal Water and Sewage Company

The Municipal Water and Sewage Company in Krakow modernized 12 pumping stations, implementing a comprehensive energy optimization system. As part of the project:

- VFDs were installed on all pumps

- A SCADA system with predictive algorithms was implemented

- Precise pressure and flow sensors were installed

- Energy monitoring was integrated with the management system

One year after system implementation, the company recorded:

- A 32% reduction in energy consumption on an annual basis

- Energy cost reduction of over $300,000 annually

- A 47% reduction in pump failures

- Return on investment achieved after 2.5 years

Practical Steps for Implementing Optimization

- Energy Audit - comprehensive analysis of the current infrastructure state and identification of areas with the greatest savings potential.

- Hardware Modernization - replacement of outdated pumps with energy-efficient models, installation of VFDs and modern sensors.

- SCADA System Implementation - implementation of a control and monitoring system with energy optimization functions.

- Personnel Training - preparing employees to operate new systems and interpret data.

- Continuous Optimization - regular analysis of operational data and adjustment of operating parameters to changing conditions.

Summary

Optimizing energy consumption in pumping stations is not only a matter of financial savings but also an element of responsible resource management. Experiences from numerous implementations show that the goal of 30% reduction in energy consumption is fully achievable when applying a comprehensive approach combining modern technologies, intelligent control algorithms, and systematic monitoring.

The HydroNexis system, with its advanced energy optimization functions, is an effective tool for achieving these goals while ensuring water supply reliability and ease of operation.

Comments (8)

Mark Newman

October 17, 2023, 14:35

Great article! In our company, we implemented similar solutions and the savings are indeed significant. The biggest challenge for us was convincing the board to make the initial investment.

Anna Smith

October 16, 2023, 09:12

Can you provide more information about specific VFD models that have proven effective in practice? We are planning a similar modernization and I'm gathering data to present to the board.

Thomas Wilson

October 15, 2023, 22:47

From my experience, the key to success is carefully matching control algorithms to the specifics of a given pumping station. Universal solutions often don't bring such spectacular effects.

Maggie Johnson

October 14, 2023, 16:20

I work in a medium-sized water utility and I'm wondering if at our scale of operation (we serve a city of 50,000 residents) such solutions will also bring measurable effects? Can smaller utilities also expect such significant savings?

Chris Adams

October 13, 2023, 08:45

Interesting approach. We applied similar solutions in our facility but with a smaller effect (about 18% savings). I think the key is precisely tailoring the entire system to the specifics of a particular infrastructure.

Add a Comment