Introduction

The Municipal Water and Sewage Utility (MWSU) is one of the largest water utilities in the country, serving over 2 million residents of the capital city. In 2022, the company faced the challenge of modernizing its outdated pump infrastructure control system, which was crucial for ensuring service reliability and optimizing operational costs.

In this case study, we analyze in detail the process of implementing the HydroNexis system at MWSU, from the planning stage, through implementation, to the evaluation of results after a year of operation. We present both the successes achieved and the difficulties encountered, as well as the methods developed to overcome them.

"Choosing the HydroNexis system proved to be a turning point in our digital transformation strategy. Finding a solution that not only optimizes current processes but also ensures scalability for the future was crucial for us."

Project Characteristics

Initial State

Before implementing the HydroNexis system, MWSU's infrastructure was characterized by:

- A distributed control system consisting of several non-integrated solutions from different manufacturers

- Limited capability for centralized monitoring and management

- High system maintenance and servicing costs

- Difficulties in rapid response to failures and anomalies

- Lack of advanced analytical tools

Energy costs related to pumping stations represented over 65% of total operational costs, and the average response time to critical failures was 78 minutes.

Project Objectives

The main goals set for the HydroNexis system implementation included:

- Integration of all pump control systems within a single platform

- Reduction of electrical energy consumption by at least 20%

- Reduction of failure response time by 40%

- Extension of pump infrastructure lifespan by 30%

- Creation of a centralized management center with full access to real-time data

- Automation of reporting and analytics processes

Implementation Scope

The project covered a total of 24 water infrastructure facilities, including:

- 8 large pumping stations

- 12 smaller local pumping stations

- 4 water intakes with deep well pumps

The installation covered over 120 pumps of various types and power ratings, with more than 450 measurement points distributed throughout the network.

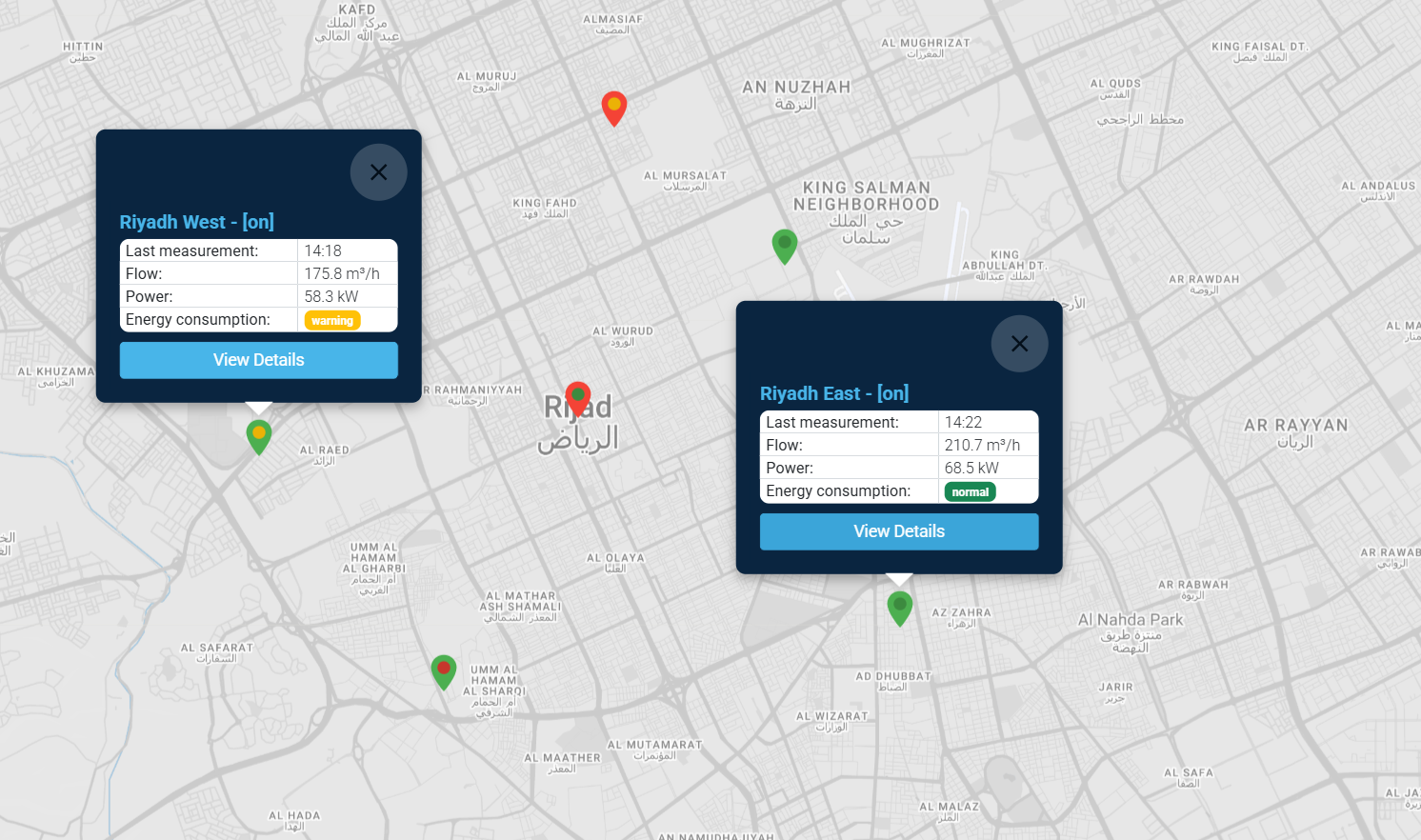

Map of facilities covered by HydroNexis system implementation

Implementation Phases

Phase 1: Analysis and Planning (2 months)

The implementation process began with a detailed analysis of the existing infrastructure and control systems. The project team consisting of MWSU engineers and HydroNexis specialists conducted:

- Technical audit of all facilities

- Analysis of operational processes and service procedures

- Identification of key performance indicators (KPIs)

- Development of a detailed implementation schedule

- Preparation of data migration strategy

At this stage, the first challenge was encountered - significant diversity of control systems in individual facilities and lack of complete technical documentation for older installations. The problem was solved by conducting additional inventory and developing dedicated integration interfaces.

Phase 2: Pilot Implementation (3 months)

To minimize risk, implementation began with a pilot project covering two pumping stations. During this phase:

- Necessary hardware was installed (servers, controllers, sensors)

- HydroNexis software was implemented in its basic version

- Integration with existing measurement systems was performed

- Key users were trained

- Functional and performance tests were conducted

During the pilot phase, the need to modify some control algorithms to better adapt them to the specifics of the water supply network was identified. Additional reporting functions were also introduced at the request of the operations department.

Phase 3: Full Implementation (6 months)

After the successful completion of the pilot project, implementation of the system in the remaining facilities began. This process was divided into three geographical stages to minimize the risk of water supply interruptions. During this phase:

- Server and network infrastructure was expanded

- Control cabinets at facilities were modernized

- New sensors and measuring transducers were installed

- The full version of the HydroNexis software was implemented

- Integration with billing and ERP systems was performed

- Management center with advanced dashboards was launched

The biggest challenge of this phase was maintaining facility operation continuity during control system migration. A strategy of parallel operation of old and new systems was applied for a transition period, which allowed for a smooth transition without interruptions in water supply.

New control center using the HydroNexis system

Phase 4: Optimization and Development (ongoing)

After completing the basic implementation, the project entered a phase of continuous optimization and development. During this phase:

- Detailed calibration of control algorithms was performed

- Advanced predictive modules were implemented

- Reporting and analytical functions were expanded

- Integration with the GIS platform was completed

- Work on a mobile module for field service teams began

Key Challenges and Solutions

| Challenge | Solution |

|---|---|

| Diversity of existing control systems and communication protocols | Development of dedicated communication interfaces and application of middleware layer to integrate different protocols |

| Maintaining operational continuity during migration | Phased implementation with period of parallel operation of old and new systems |

| Staff resistance to new technologies | Comprehensive training program and inclusion of technical staff in the user interface design process |

| Need to adapt standard algorithms to specific network conditions | Modification of control algorithms in collaboration with local engineers |

| Integration with existing business systems | Creation of dedicated API layer and application of data exchange standards |

Results After 12 Months

One year after the full implementation of the HydroNexis system, MWSU conducted a detailed analysis of the effects, which showed:

Energy Efficiency

- Reduction of energy consumption by 27.4% across the entire network

- Optimization of pump operation schedule in relation to energy tariffs

- Reduction in the number of pump starts by 34%, which translated into lower startup energy consumption

Operational Reliability

- Reduction of average failure detection time from 28 to 3 minutes

- Reduction of total downtime by 62%

- Reduction in the number of unplanned service interventions by 47%

- Improvement in water demand forecasting accuracy by 38%

Economic Effects

- Total energy cost savings: $800,000 annually

- Reduction in maintenance and repair costs: $350,000 annually

- Reduction in administrative costs related to reporting: $200,000 annually

- Estimated return on investment (ROI) period: 2.7 years

Additional Benefits

- Improvement in working conditions and technical staff satisfaction

- Better insight into network functioning and ability to make data-driven decisions

- Standardization of operational procedures and increased process transparency

- Compliance with regulatory requirements regarding environmental reporting

Conclusions and Recommendations

The implementation of the HydroNexis system at MWSU can be considered a success that brought measurable benefits in terms of operational, energy, and economic efficiency. Based on the experiences from this project, the following recommendations can be formulated for similar implementations:

- In-depth preliminary analysis - detailed assessment of existing infrastructure and processes is key to proper implementation planning.

- Phased approach - starting with a pilot project allows for early identification of problems and adaptation of the solution before full implementation.

- Staff involvement - including operational employees in the design and implementation process increases acceptance of the new system.

- Flexibility in adaptation - readiness to modify standard solutions to match the specific needs of the organization.

- Long-term perspective - planning implementation as a continuous improvement process rather than a one-time project.

MWSU plans further development of the HydroNexis system, including integration with water quality monitoring systems, expansion of predictive functions, and implementation of mobile applications for field service teams. The application of augmented reality (AR) technology to support maintenance work is also being considered.

"Modernization of IT infrastructure in the water sector is no longer an option but a necessity. Our experience with implementing HydroNexis shows that investing in modern SCADA systems translates into measurable financial benefits while improving service reliability for residents."

Comments (5)

Andrew Cooper

September 8, 2023, 10:23

Very interesting case analysis. I work at a smaller water utility and we're considering a similar implementation. Is the HydroNexis system scalable downward for smaller enterprises? What would the implementation process look like for a utility serving a 60,000-resident city?

Barbara Nowak

7 września 2023, 15:47

Artykuł koncentruje się głównie na technicznych aspektach wdrożenia. Chciałabym dowiedzieć się więcej o aspektach organizacyjnych - jak wyglądało szkolenie pracowników i jak długo trwał proces adaptacji zespołu do nowego systemu?

Marek Wiśniewski Autor

7 września 2023, 17:30

Dziękuję za pytanie, Barbaro. Proces szkoleniowy obejmował 3 etapy: szkolenie podstawowe dla wszystkich pracowników (2 dni), zaawansowane dla operatorów (5 dni) oraz specjalistyczne dla administratorów systemu (10 dni). Pełna adaptacja zespołu trwała około 3 miesięcy, przy czym kluczowe było utworzenie zespołu ambasadorów zmiany, którzy wspierali kolegów w codziennej pracy z nowym systemem.

Krzysztof Jankowski

6 września 2023, 21:12

Z perspektywy cyberbezpieczeństwa, jakie zabezpieczenia zostały zastosowane przy integracji systemu HydroNexis z istniejącą infrastrukturą? Infrastruktura krytyczna jak wodociągi jest przecież częstym celem cyberataków.

Anna Zielińska

6 września 2023, 14:05

Czy korzystaliście z dofinansowania unijnego przy realizacji tego projektu? Jeśli tak, z jakiego programu i jaki był poziom dofinansowania? Planujemy podobną inwestycję i szukamy możliwości zewnętrznego finansowania.

Tomasz Wójcik

5 września 2023, 18:33

Świetna analiza! Jako były pracownik MPWiK mogę potwierdzić, że wdrożenie HydroNexis znacząco poprawiło komfort pracy operatorów. Szczególnie doceniam moduł analityczny, który pozwala na szybkie diagnozowanie problemów.

Dodaj komentarz