Introduction

Recent years have witnessed significant progress in predictive maintenance technologies for pumping systems. Particularly interesting is an innovative method based on precise analysis of pressure and flow parameters that enables detection of potential failures in deep well pumps before they actually occur. In this article, we present detailed information about this breakthrough technology and its practical applications in modern SCADA systems.

Operating Principle of the Technology

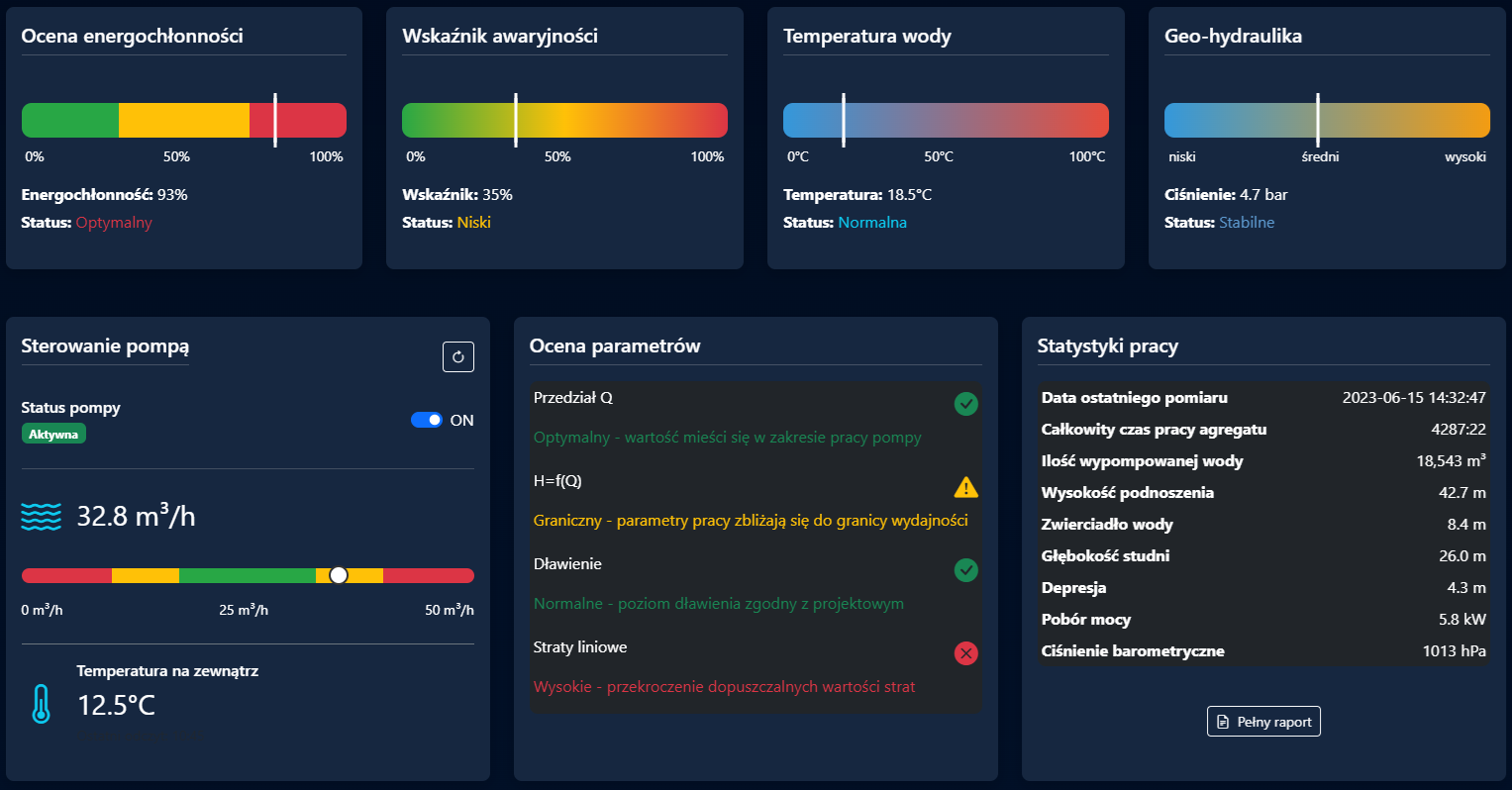

The core of the described solution is an advanced monitoring system that analyzes key operational parameters of submersible pumps in real-time:

- Inlet and outlet pump pressure

- Water flow at various points in the system

- Vibrations and noise associated with pump unit operation

- Electrical energy consumption

- Temperature of the motor and mechanical components

Block diagram of the deep well pump parameter monitoring system

Visualization of data collected by the monitoring system

The system utilizes advanced data analysis algorithms that can detect symptoms of approaching failures well in advance based on changes in monitored parameters. This makes it possible to schedule maintenance and repair work at an optimal time, before a serious malfunction occurs.

Key System Components

When implementing the described technology, attention should be paid to several key elements:

- Network of precision sensors - measurements of pressure, flow, vibration, and other parameters require advanced transducers with high accuracy and resistance to environmental conditions.

- Data acquisition system - responsible for collecting, pre-processing, and transmitting measurements to the central analytical unit.

- Data processing unit - equipped with pattern analysis, artificial intelligence, and machine learning algorithms that identify anomalies and predict potential problems.

- User interface - providing intuitive visualization of data, alarms, and maintenance recommendations.

- Decision-making system - in advanced implementations, it can automatically respond to detected anomalies, e.g., by changing pump operating parameters.

Economic Benefits

Implementation of predictive maintenance technology for pumps brings measurable economic benefits for water utilities:

Main Financial Benefits

- Reduction of unplanned downtime costs - by up to 70%

- Decrease in energy consumption - from 15% to 25%

- Extended lifespan of pumps and units - by an average of 30%

- Optimization of maintenance costs - savings of 20-30%

- Reduced risk of serious failures - repair cost reduction of 40-60%

Experience from implementations of this technology shows that the total return on investment typically occurs within 12-24 months, depending on the size of the infrastructure and the previous technical condition of the equipment.

Case Study: Implementation in a Water Utility in Saudi Arabia

In 2022, a water utility in Riyadh (Saudi Arabia) decided to implement the described technology in 18 deep well pump stations operating in exceptionally challenging desert conditions. After 12 months of system operation, the following results were recorded:

Team responsible for project implementation in Saudi Arabia

| Parameter | Before Implementation | After Implementation | Change |

|---|---|---|---|

| Number of unplanned downtime events | 42 / year | 11 / year | -74% |

| Electrical energy consumption | 2.85 million kWh | 2.11 million kWh | -26% |

| Repair costs | 1.2 million SAR / year | 0.39 million SAR / year | -68% |

| Anomaly response time | 6-72 hrs. | 0.2-3 hrs. | -96% |

"Predictive maintenance technology has radically changed how we manage our water infrastructure. In harsh desert conditions, where temperatures often exceed 45°C, the reliability of pumping systems is absolutely critical. Thanks to this solution, we have significantly reduced the number of failures and optimized operational costs."

Ahmad Al-Saleh, Infrastructure Director, Saudi Arabia

As demonstrated, the implementation of predictive maintenance technology has brought significant operational and financial benefits, even in exceptionally demanding desert conditions. Particularly important is the reduction of unplanned downtime, which not only presents an economic problem but can also lead to interruptions in water supply for residents in regions with limited access to water resources.

Integration with SCADA Systems

One of the key advantages of the described technology is its easy integration with existing SCADA systems. Through standard communication protocols (Modbus TCP/IP, OPC UA, MQTT), data from the monitoring system can be transmitted to supervisory water infrastructure management systems.

In the case of the HydroNexis system, integration occurs through dedicated modules that ensure seamless data exchange and enable full utilization of predictive algorithms within the existing IT infrastructure.

Our team of system integration specialists:

John Smith

Chief Systems Architect

Anna Nolan

Integration Specialist

Peter Willis

Systems Engineer

Agatha Green

DevOps Engineer

Future of Technology and Development

Intensive work is currently underway to develop the described technology in several key areas:

- Application of advanced deep learning algorithms for even more accurate prediction of potential failures

- Integration with energy management systems for further optimization of operating costs

- Development of self-learning systems that automatically adjust pump operating parameters to changing conditions

- Development of mobile user interfaces enabling system monitoring and management from portable devices

- Creation of predictive systems for entire water supply networks, not just individual pump stations

It is anticipated that within the next 3-5 years, predictive maintenance technologies will become standard in the water industry, contributing to further increases in water supply reliability and reductions in operational costs.

Research and development team working on future generations of technology:

Dr. Mark Adams

R&D Manager

Dr. Katherine Quinn

AI & Machine Learning

Prof. Robert Major

System Hydraulics

Dr. Thomas Dowd

Signal Processing

Summary

Predictive maintenance technology for submersible pumps based on pressure and flow analysis represents a breakthrough solution for water utilities. Through advanced data analytics, early detection of potential problems is possible, which translates into significant financial savings, extended equipment lifespan, and increased water supply reliability.

Implementation of this technology within the HydroNexis system allows for full integration with existing SCADA systems, facilitating the implementation process and maximizing the benefits of applying modern analytical solutions.

Comments (4)

Martin Cooper

November 15, 2023 | 10:23

Excellent article! We've implemented similar technology in our water utility and the savings are indeed significant. I particularly like the section on integration with existing SCADA systems - the process is indeed much simpler than we initially assumed.

Anna Wilson

November 16, 2023 | 14:45

I'm wondering about data security in such systems. Do you have any experience with securing these types of solutions against cyber threats? Water infrastructure is critical from a security perspective after all.

Jacob Newman

November 17, 2023 | 09:12

Thank you for your question, Ms. Wilson. This is indeed a critical issue! In our implementations, we use multi-layered security measures: network segregation, data encryption, multi-level user authentication, and regular security audits. Additionally, HydroNexis systems can operate in an Internet-isolated mode, which significantly reduces the vector of potential attacks. I'd be happy to share more details - please feel free to contact us through the form on our website.

Paul Newman

November 18, 2023 | 16:30

Are you planning a webinar or training regarding the described technologies? I'm from a smaller water utility and we would like to learn more about the possibilities of implementing similar solutions at a scale appropriate for smaller infrastructure.

Maria Davis

November 19, 2023 | 11:05

Hello Mr. Newman, I'm pleased to inform you that we're planning a series of webinars on predictive maintenance for water infrastructure in January 2024, with sessions dedicated to smaller utilities. We'll be discussing scalable solutions and implementation options tailored to different needs and budgets. Registration will open in December - please stay tuned to our website and social media!

Andrew Brooks

November 20, 2023 | 08:17

Very interesting solution! Have your systems also proven effective in extreme mountain climate conditions? I manage water infrastructure in a Carpathian resort and we face significant temperature fluctuations and frequent power outages.

Add a Comment