Introduction

In an era of rising energy and fuel costs, coupled with increased emphasis on operational efficiency, businesses are increasingly seeking solutions for precise monitoring and optimization of fuel consumption. This applies to companies with vehicle fleets as well as industrial facilities using power generators or heating systems. In this article, we present modern solutions for intelligent fuel monitoring that enable not only level tracking but also anomaly detection and prevention of potential misuse.

Challenges of Traditional Fuel Management

Traditional methods of monitoring fuel inventory and consumption involve numerous challenges:

- Limited measurement accuracy leading to reporting discrepancies

- Delays in detecting potential leaks or fuel theft

- Lack of real-time monitoring capabilities for fuel consumption

- High level of human error in manual measurements and documentation

- Difficulties in identifying inefficiencies in fuel-powered systems

Traditional fuel level measurement methods and their numerous limitations

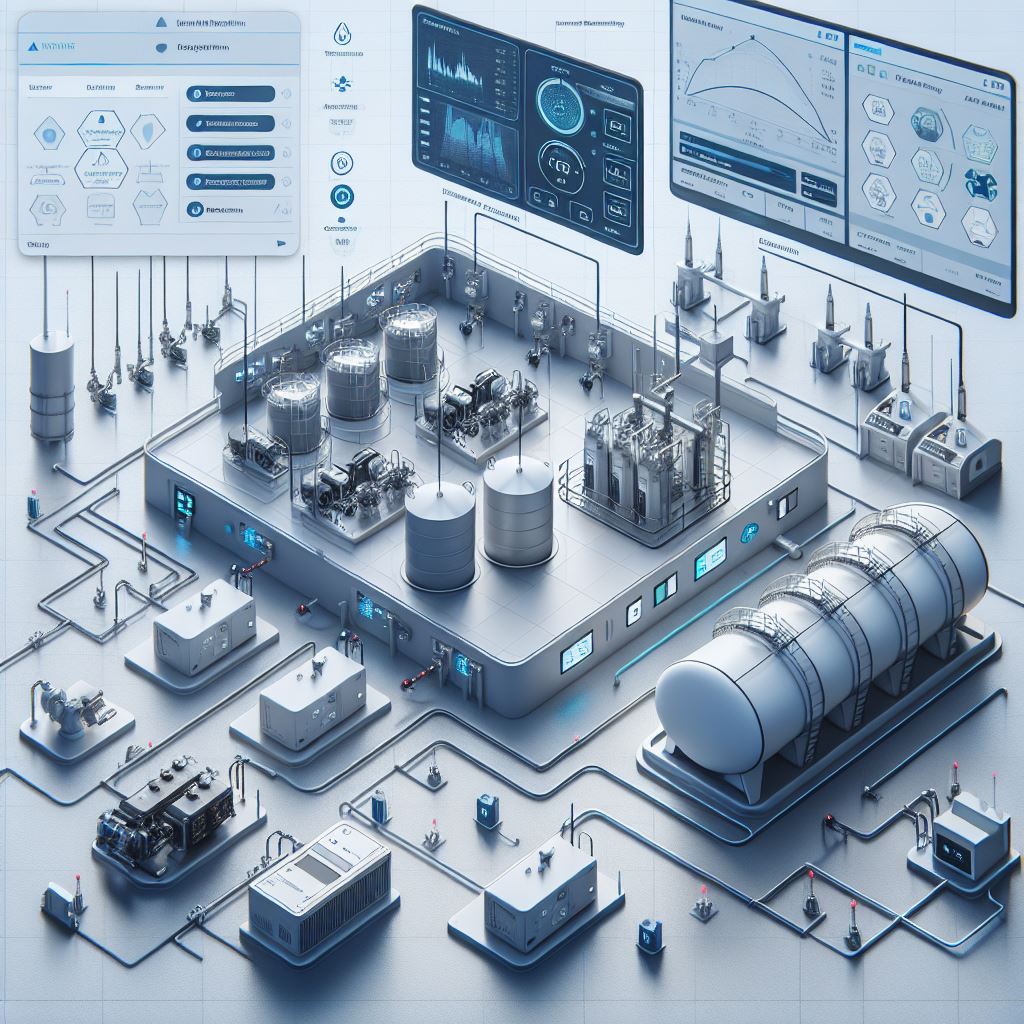

Modern system for real-time fuel parameter monitoring

According to research conducted by the Institute of Logistics and Warehousing, irregularities in fuel management can generate losses constituting up to 5-8% of total operational costs in transportation and manufacturing companies. Additionally, the lack of precise data prevents effective process optimization and budget planning.

Components of Intelligent Fuel Monitoring System

Modern fuel monitoring solutions consist of several key elements:

- Precision fuel level sensors - utilizing ultrasonic, capacitive, or magnetostrictive technologies for accurate fuel quantity measurement

- Quality parameter sensors - monitoring temperature, density, and other parameters affecting combustion efficiency

- Communication modules - ensuring data transmission to the central system via GSM/GPRS, LTE, Wi-Fi, or industrial protocols

- Analytical software - processing collected data and generating reports and alerts

- User interfaces - accessible on various devices, enabling easy access to data and system management

Case Study: Implementation in a Transportation Company

A transportation company based in Poznan, with a fleet of 120 heavy vehicles, decided to implement an intelligent fuel monitoring system. The project included:

Fuel Monitoring Project Scope

- Installation of precision fuel probes in all vehicle tanks

- Installation of flow sensors on power generator supply lines at the transport base

- Implementation of a telemetry system collecting real-time data

- Integration with existing fleet management software

- Implementation of algorithms detecting anomalies in fuel consumption

- Personnel training on new system operation

After one year of implementation, the company recorded significant benefits. Below are the key performance indicators:

Team responsible for fuel monitoring project implementation

| Parameter | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Annual fuel consumption (l) | 1,450,000 | 1,276,000 | -12% |

| Detected cases of unauthorized fuel withdrawal | 8 / year | 47 / year | +487% |

| Consumption reporting accuracy | ±7% | ±0.5% | +92.9% |

| Reaction time to consumption anomalies | 48 hours | 15 minutes | -99.5% |

"The implementation of an intelligent fuel monitoring system has completely transformed our approach to cost management. Not only have we significantly reduced fuel consumption and eliminated cases of misuse, but we've also obtained valuable data that allowed us to optimize routes and maintenance schedules. The system paid for itself in just 8 months and now generates continuous savings."

Paul Adams, CEO, Transportation Company

Advanced Features of Modern Fuel Monitoring Systems

Contemporary solutions offer a range of advanced analytical and control functions:

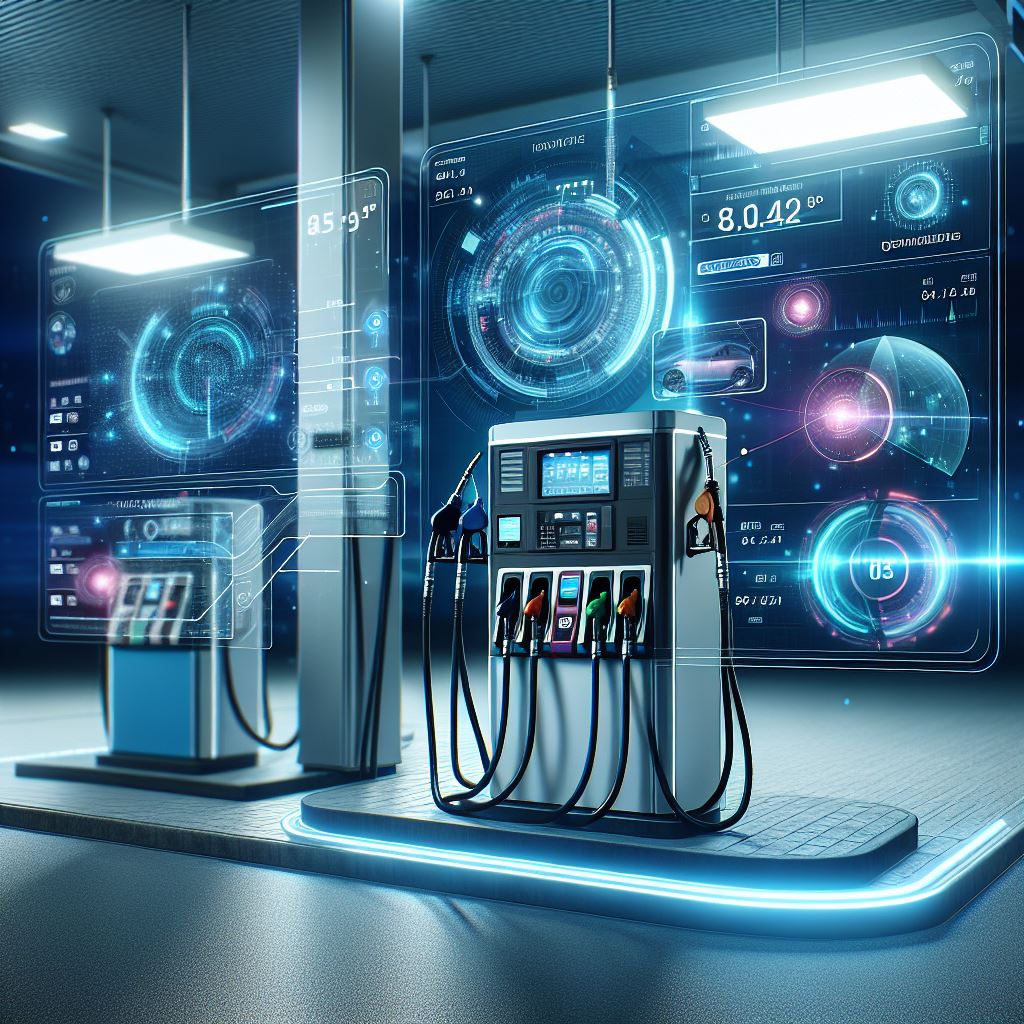

- 1. Detection of refueling and fuel withdrawal with precise geolocation and event timing

- 2. Automatic alerts for sudden fuel level drops suggesting theft or leakage

- 3. Correlation of fuel consumption with operating conditions (load, temperature, route)

- 4. Analysis of driver behavior and its impact on fuel consumption

- 5. Identification of inefficiencies in generator operation and supply systems

- 6. Predictive planning for refueling and fuel system maintenance

- 7. Automated accounting and tax reporting

- 8. Integration with fleet management and ERP systems

- 9. Comparative analysis of fuel efficiency across vehicles and equipment

- 10. Monitoring of fuel quality parameters

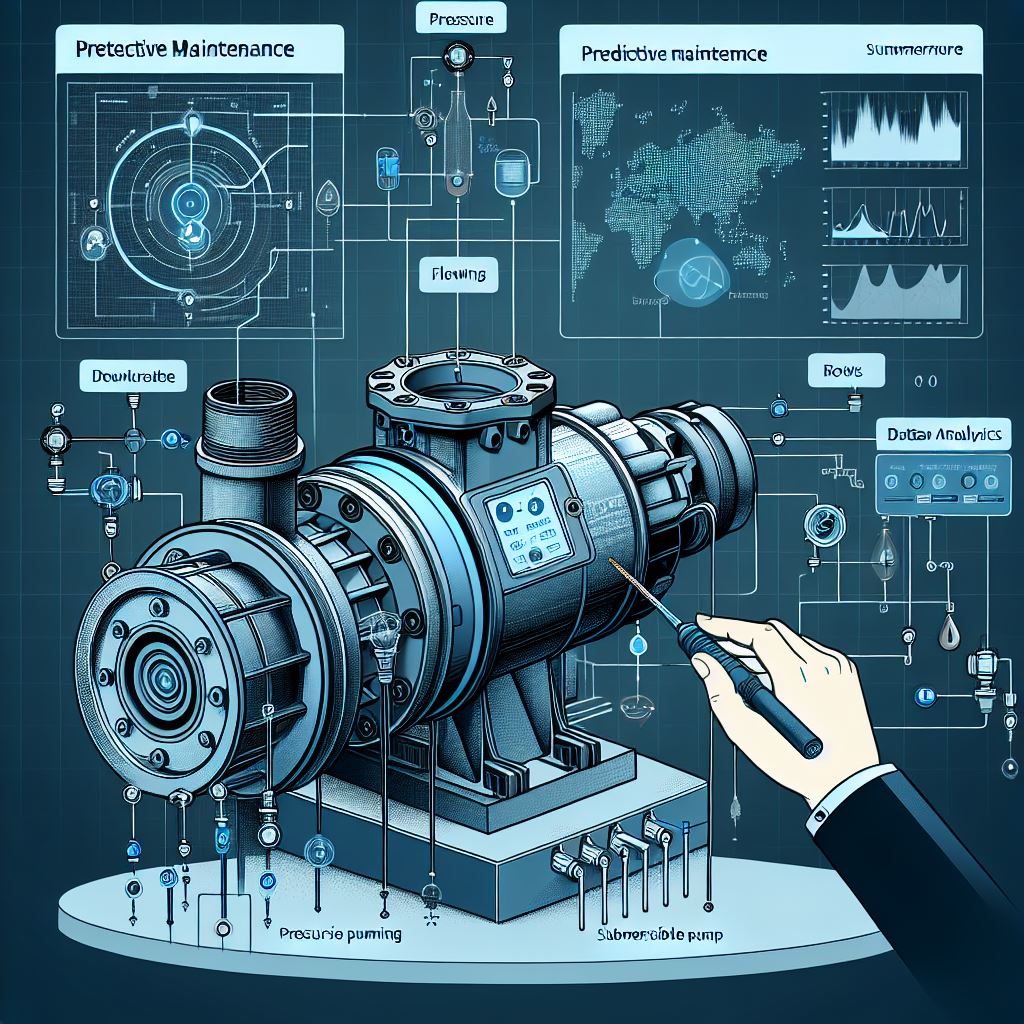

Application in Power Generators

Intelligent fuel monitoring is particularly important for power generators, especially those serving as emergency power sources for critical infrastructure:

- Continuous operational readiness - ongoing fuel level control ensuring full readiness in emergency situations

- Periodic test optimization - monitoring efficiency during routine generator tests

- Parameter degradation detection - identification of technical problems based on changes in fuel consumption characteristics

- Performance analysis - examination of the ratio between fuel consumption and generated electrical energy

- Lifecycle management - optimization of maintenance and replacement schedules based on actual operational data

Research and development team working on new fuel monitoring technologies:

Dr. Adam Cooper

R&D Manager

Anna Norton, MSc

Sensor Specialist

Dr. Peter Johnson

Data Analyst

Katherine Williams, MSc

Software Engineer

FuelSense System - Comprehensive Fuel Monitoring Solution from HydroNexis

In response to growing market demand, HydroNexis has developed the advanced FuelSense system, offering a comprehensive solution for monitoring fuel in stationary tanks, mobile containers, and power generators.

- Fuel level monitoring

- Basic notifications

- Daily reporting

- Mobile application access

- Email notifications

- All Basic features

- Real-time consumption analysis

- Anomaly detection

- ERP system integration

- Advanced reporting

- All Pro features

- Predictive AI algorithms

- Comprehensive quality monitoring

- API for custom integrations

- Dedicated 24/7 support

Implementation and Integration Process

Fuel monitoring system implementation follows a proven scheme:

- Existing infrastructure audit - analysis of tanks, generators, and existing measurement systems

- System design - selection of appropriate sensors and communication modules

- Hardware installation - mounting of sensors and telemetry devices

- Software configuration - customization of the system to client-specific requirements

- Integration with existing systems - connection with ERP, fleet management systems, and others

- Training - preparing personnel for effective system utilization

- Calibration and validation - system tuning and measurement accuracy verification

- Post-implementation support - ongoing technical service and updates

Future Perspectives for Fuel Monitoring Technology

In the coming years, we expect significant development of fuel monitoring technology in several key areas:

- Sensor miniaturization while maintaining high accuracy

- Development of wireless systems operating in challenging industrial environments

- Broader application of artificial intelligence for analyzing consumption patterns and failure prediction

- Integration with blockchain systems to ensure immutability of fuel transaction data

- Utilization of drones for inspection and monitoring of large tanks

Summary

Intelligent fuel monitoring systems are now an indispensable element of effective resource management in many industries. They offer not only precise information about fuel status but also advanced analytical functions that enable process optimization, cost reduction, and operational safety improvement.

Investment in such solutions typically returns in a very short time, and long-term benefits significantly exceed initial expenditures. For businesses where fuel constitutes a significant component of operational costs, implementing a modern monitoring system becomes not just a choice but a business necessity in the face of growing competition and pressure to optimize expenses.

Comments (3)

Robert Davis

December 7, 2023 | 09:15

We implemented a similar system in our transportation company and I must admit that the savings exceeded our expectations. The anomaly detection in consumption proved particularly valuable, allowing us to quickly respond to technical problems and prevent more serious failures. Does the FuelSense system also enable driver behavior analysis and generation of personalized recommendations for them?

Christopher Wilson

December 7, 2023 | 11:32

Thank you for your comment, Robert! Yes, FuelSense Pro and Enterprise offer driver behavior analysis functionality that correlates fuel consumption with telematic system data (acceleration, braking, engine RPM). The system automatically generates personalized recommendations for drivers and enables the creation of incentive programs based on fuel efficiency. Our clients report an additional 5-7% savings after implementing this module.

Martin Knight

December 8, 2023 | 14:22

Interesting article! I manage a network of emergency generators in commercial facilities and I'm wondering if the FuelSense system can detect degradation of fuel quality in tanks that store fuel for extended periods? The issue with fuel sitting for months and its quality is critical for us in ensuring reliability in emergency situations.

Monica Jenkins

December 10, 2023 | 08:46

Can the system work with generators from different manufacturers and of varying ages? We have rather heterogeneous infrastructure, and I'm concerned about integration issues. Additionally, how is data security handled, especially for wireless transmission of fuel inventory information?

Add a Comment